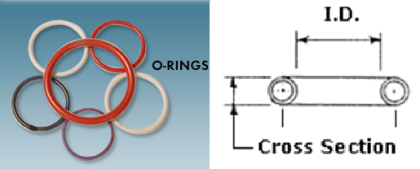

FEP / PFA Encapsulated O-Rings:

Combining the best qualities of two gasket/o-ring materials, FEP or PFA (see below) on the exterior to handle aggressive chemical and temperature environments, coupled with the more resilient elastomer on the interior (fully encapsulated) to provide proper shape and elasticity under load. Available from 0.063” cross-section up to 1-1/4” cross-section size. Used primarily as a static (non-dynamic) axial or radial seal. Manufactured in sizes to AS 568A industry standards. Also available in metric (ISO) sizes. Square (or rectangular) cross-sections are available for added sealing surface, as well.

Silicone is the standard (fully encapsulated) elastomer, with Viton® or EPDM also available as options.

FEP (fluorinated ethylene propylene) exterior surface offered as standard rated up to +400.deg.F temperature;

PFA (perfluoroalkoxy) used to reach upwards to +500.deg.F temperature in severe service environments.

Benefits of FEP encapsulated o-rings:

● excellent chemical resistance to most all industrial chemicals;

● low coefficient of friction;

● low compression set;

● temperature range -75.deg.F to +400.deg.F;

● choice of elastomer core;

● FDA-compliant materials available; USP Class VI approved materials available.

Benefits of PFA encapsulated o-rings (same as above, with the following added benefits):

● higher temperature applications up to +500.deg.F;

● higher mechanical strength with longer flex life;

● low vapor permeation;

● excellent stress- and crack-resistance;

● longer wearability.

Square (or rectangular) cross-sectional seals / gaskets:

● larger sealing surface vs. an o-ring profile;

● less force required for sealing, effecting a more positive seal.

|

Cross-section (in.) |

Cross-section (mm) |

(FEP or PFA) wall thickness (in.) |

Groove depth (in.) |

Groove width (in.) |

|

.063 ± .004 |

1.60 ± 0.10 |

0.01 |

0.046 |

0.087 |

|

.070 ± .004 |

1.78 ± 0.10 |

0.01 |

0.049 |

0.1 |

|

.079 ± .004 |

2.00 ± 0.10 |

0.01 |

0.057 |

0.111 |

|

.094 ± .004 |

2.40 ± 0.10 |

0.01 |

0.069 |

0.127 |

|

.098 ± .004 |

2.50 ± 0.10 |

0.01 |

0.074 |

0.132 |

|

.103 ± .004 |

2.62 ± 0.10 |

0.01 |

0.078 |

0.137 |

|

.118 ± .004 |

3.00 ± 0.10 |

0.01 |

0.088 |

0.157 |

|

.122 ± .004 |

3.10 ± 0.10 |

0.01 |

0.092 |

0.161 |

|

.125 ± .004 |

3.20 ± 0.10 |

0.01 |

0.095 |

0.164 |

|

.134 ± .005 |

3.40 ± 0.13 |

0.01 |

0.104 |

0.174 |

|

.139 ± .005 |

3.53 ± 0.13 |

0.012 |

0.108 |

0.178 |

|

.150 ± .006 |

3.80 ± 0.15 |

0.012 |

0.118 |

0.191 |

|

.157 ± .006 |

4.00 ± 0.15 |

0.012 |

0.125 |

0.201 |

|

.170 ± .006 |

4.30 ± 0.15 |

0.015 |

0.135 |

0.217 |

|

.177 ± .006 |

4.50 ± 0.15 |

0.015 |

0.14 |

0.226 |

|

.187 ± .006 |

4.75 ± 0.15 |

0.015 |

0.147 |

0.238 |

|

.197 ± .006 |

5.00 ± 0.15 |

0.015 |

0.157 |

0.248 |

|

.210 ± .006 |

5.33 ± 0.15 |

0.015 |

0.165 |

0.267 |

|

.217 ± .007 |

5.50 ± 0.18 |

0.015 |

0.172 |

0.276 |

|

.225 ± .007 |

5.70 ± 0.18 |

0.015 |

0.178 |

0.284 |

|

.236 ± .007 |

6.00 ± 0.18 |

0.015 |

0.19 |

0.296 |

|

.250 ± .008 |

6.35 ± 0.20 |

0.02 |

0.2 |

0.313 |

|

.275 ± .008 |

7.00 ± 0.20 |

0.02 |

0.225 |

0.338 |

|

.295 ± .012 |

7.50 ± 0.30 |

0.02 |

0.24 |

0.364 |

|

.315 ± .015 |

8.00 ± 0.38 |

0.02 |

0.257 |

0.39 |

|

.331 ± .015 |

8.40 ± 0.38 |

0.02 |

0.267 |

0.41 |

|

.354 ± .020 |

9.00 ± 0.30 |

0.02 |

0.29 |

0.434 |

|

.375 ± .020 |

9.53 ± 0.38 |

0.02 |

0.306 |

0.46 |

|

.394 ± .020 |

10.00 ± 0.51 |

0.02 |

0.322 |

0.484 |

|

.437 ± .020 |

11.10 ± 0.51 |

0.03 |

0.355 |

0.53 |

|

.472 ± .020 |

12.00 ± 0.51 |

0.03 |

0.393 |

0.571 |

|

.500 ± .020 |

12.70 ± 0.51 |

0.03 |

0.401 |

0.62 |

|

.562 ± .025 |

14.30 ± 0.64 |

0.03 |

0.45 |

0.689 |

|

.591 ± .025 |

15.00 ± 0.64 |

0.03 |

0.466 |

0.736 |

|

.625 ± .025 |

15.90 ± 0.64 |

0.03 |

0.5 |

0.77 |

|

.708 ± .025 |

18.00 ± 0.64 |

0.03 |

0.565 |

0.9 |

|

.750 ± .025 |

19.00 ± 0.64 |

0.03 |

0.58 |

0.97 |

|

.787 ± .025 |

20.00 ± 0.64 |

0.03 |

0.6 |

1.032 |

|

1.000 ± .035 |

25.40 ± 0.89 |

0.045 (PFA only) |

0.757 |

1.27 |

|

1.250 ± .050 |

31.75 ± 1.27 |

0.045 (PFA only) |

0.94 |

1.585 |